Our history in few lines

Notre société a assis sa réputation et sa notoriété sur des gages de qualité : souplesse, résistance, non irritant pour la peau, extra léger (rendement maximum au kg.)

Depuis plus de 50 ans, nos bracelets élastiques ont établi leur renommée dans des milieux aussi divers que l’agriculture, l’industrie, la papeterie, le conditionnement

Nos dernières innovations sur le produit nous ont conduit a nous diversifier dans de nouveaux domaines tel que : la Mode, le Design et la Sérigraphie.

Quelque Notions de Base — Bracelets Elastiques

Comment Mesurer un Bracelet Elastique

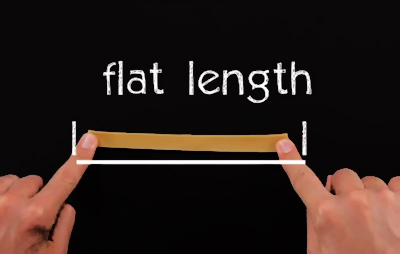

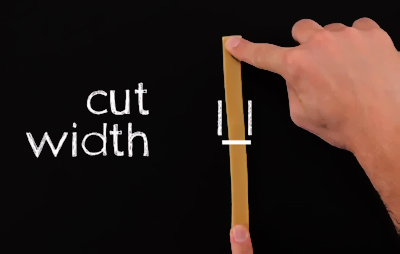

Les Bracelets Elastiques sont mesurés via trois dimensions: Longueur, Largeur et l’Epaisseur. — [ consultez notre tableau avec les tailles disponibiles ]

1. Pincez une des bracelet élastique à chaque extrémité comme pour jeter les plats de bande. La distance de l’extrémité de fin est la longueur de la bande.

1. Pincez une des bracelet élastique à chaque extrémité comme pour jeter les plats de bande. La distance de l’extrémité de fin est la longueur de la bande. 2. Mesures de la largeur de bande, perpendiculaire à la longueur.

2. Mesures de la largeur de bande, perpendiculaire à la longueur. 3. La mesure d’épaisseur de la paroi de la bande. Epaisseur est généralement comprise entre 1,1 mm – 2,5 mm.

3. La mesure d’épaisseur de la paroi de la bande. Epaisseur est généralement comprise entre 1,1 mm – 2,5 mm.

La Fabrication

Les bracelet élastique sont fabriqués par extrusion du caoutchouc dans un long tube de fournir sa forme générale, en mettant les tubes sur des mandrins, le durcissement du caoutchouc par la chaleur, puis le trancher à travers la largeur du tube en petites bandes. Cela provoque le tube pour diviser en plusieurs sections, la création d’une bracelet élastique.

Notre Produits sont Evironmentally Friendly

Des études ont montré que les arbres à caoutchouc convertir le dioxyde de carbone à un taux comparable à voire meilleure que celle de la forêt naturelle. Le potentiel de caoutchouc naturel pour séquestrer le carbone de l’atmosphère pour soutenir l’écosystème est largement reconnu et adopté pour la création de nouvelles forêts ou à des fins de reboisement.

En plus d’être respectueux de l’environnement, la plupart de nos bracelet élastique sont fabriqués à partir de latex, une ressource renouvelable rapidement.